AMS BEVERAGE MIXER

Soft Drinks are increasingly attractive, new flavours are satisfying consumer´s thirst.

And AMS guarantees high precision to MIX any drink to perfection.

Our 3 AMS MIX Modules serve different applications. The AMS BATCH MIX is suitable for smaller-scale systems. AMS INLINE MIX is a fully integrated and automated system, where soft drink mixing and filling takes place simultaneously. AMS MULTI MIX is especially designed for multi component soft drink mixing with short changeover rates.

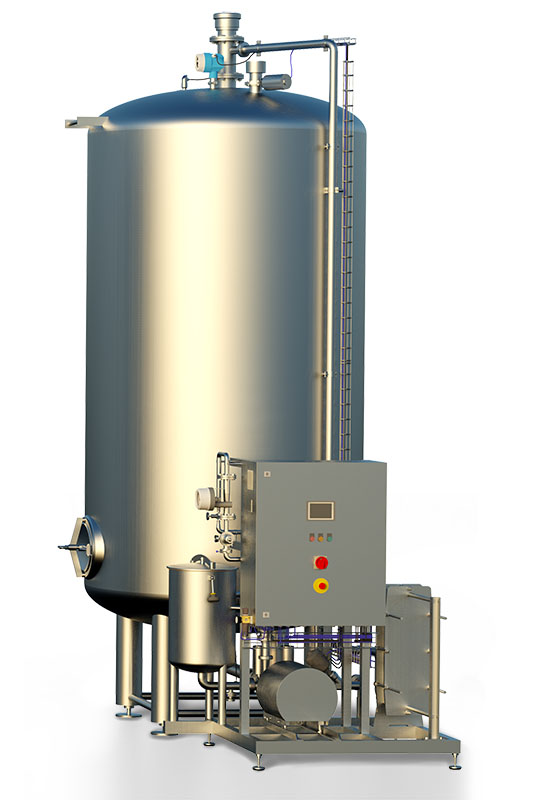

AMS BATCH MIX

Batch mixing is ideal for smaller quantities and has the advantage that a very thorough traceability of each batch is possible. Also, a batch can be tested, and then released for filling. Deviations within the batch are practically eliminated with our system.

Another feature is the simplicity of the system. The system can be easily operated, even by less skilled personnel. All the ingredients are added, weighed and the beverage batch is finished.

Two compelling reasons that tip the balance in favour of our AMS BATCH MIX: the assurance of the product quality and the simplicity.

The AMS BATCH MIX is a 2-in-1 module for production of mixed beverages and for water degassing. And this is not just any mixing plant, but a system with unsurpassed accuracy and very simple handling. There is no mixing procedure that leads to perfect results so rapidly, even with components that are difficult to mix.

Design options:

- as a pure water degassing plant (reasonably priced, buffer effect of stripping gas, low gas consumption)

- for production of finished mixed beverages in small batches

- for production of finished mixed beverages in big batches and 5 tanks per AMS BATCH MIX Skid (continuous production)

- for production of fruit mixed beverages

- for production of flavoured dairy drinks

- for production of mixed beer drinks

- for reproducible accurate production of beer brands (in BBT) with varying original extract

AMS BATCH MIX skid can be installed with locally purchased or even existing tanks further increasing the return on invest

AMS INLINE MIX

In the beverage industry, mixing describes a final in-line blending system for production of a finished beverage. AMS designed a technology of mixer series to adapt various needs of our customers. To standardise individual areas, our mixers consist of modules, which are part of the system as required.We assemble your mixer from the elements you require. From small-scale systems, where the finished syrup is dispensed from a single IBC container only, up to the AMS MULTI MIX, a multicomponent mixer, everything is possible.

1. Buffer and Homogenisation

This module ensures that product quality remains consistent, even if frequent stops occur. This module can be omitted if a buffer tank is placed in line before the filling machine and if this buffer tank has a separate inlet and a separate outlet to achieve a final homogenisation.

2. Carbonation + Syrup dosing

Core of the system is the dosing module. Here all product components are mixed together with maximum possible accuracy. If there are deviations from the tolerance, the flow will be stopped immediately. The dosing module can be ordered as a single component mixer or with several dosing points.

3. Water Degassing

The necessary residual oxygen of 0.08 ppm (starting value 0.8 ppm in the raw water) for the soft drinks can be achieved with our combined spray and rectification column in one pass. If an even lower residual oxygen value is required, then the system will be equipped with a higher column.

AMS INLINE MIX is available in 3 standard series for each capacity.

| AMS INLINE MIX 50 | 15m³/h | (150 hl/h) |

| AMS INLINE MIX 65 | 25m³/h | (250 hl/h) |

| AMS INLINE MIX 80 | 35m³/h | (350 hl/h) |

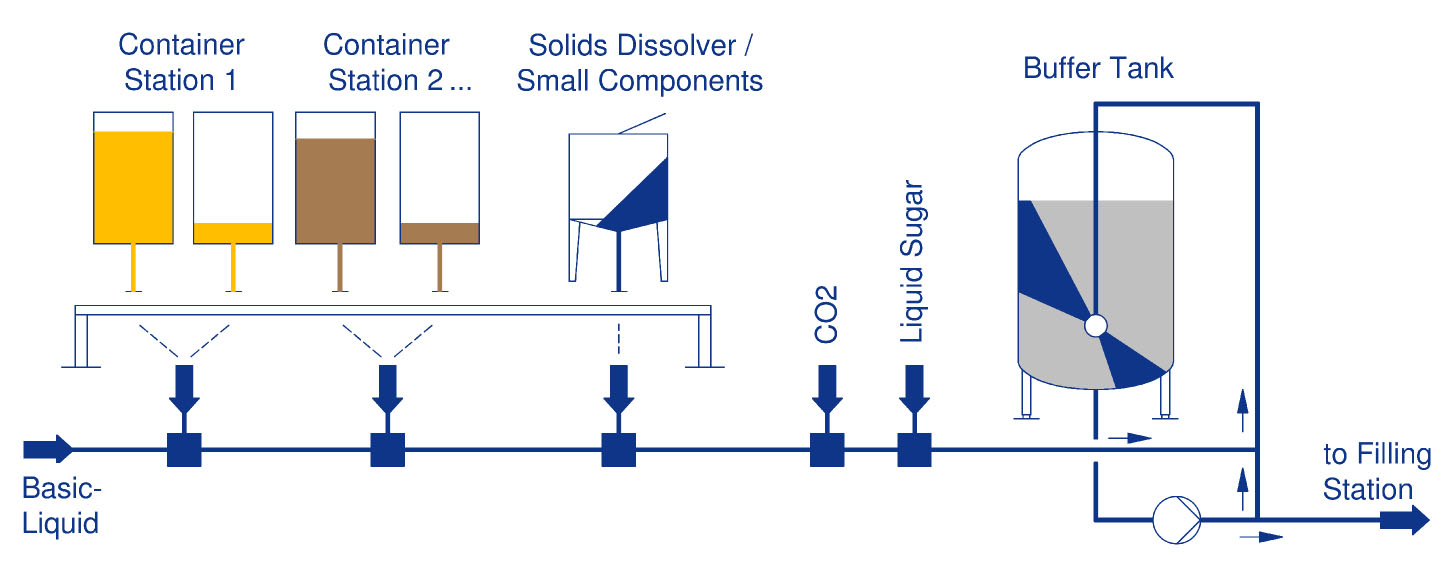

AMS MULTI MIX

The AMS MULTI MIX blending system is the optimal soft drink solution when the sugar syrup is not to be used as a carrier of the soft drink components. This may be the case when the variety of different end products makes the stocking with many types of syrup laborious, or when sugar syrup is not part of each beverage, and therefore not available as carrier of the ingredients. The AMS MULTI MIX allows maximum flexibility during soft drink production. From lightly flavoured drinks, sugar-free light drinks, fruit juice blends to beer mix, there are no restrictions. The product changeover is mainly automatic and takes just a few minutes.

There is no competitive system available on the market, which allows a higher dosing and mixing accuracy than our AMS MULTI MIX, promised! All ingredients of the soft drinks are added inline free of pulsation and can therefore be accurately measured. The highest accuracy is ensured, whether the dosing rate is large or only carried out in homeopathic doses. AMS achieves this accuracy with robust dosing lines in relatively large pipe diameters. All dosing lines can therefore be cleaned with a high CIP flow rate.

The system can be adapted modularly to the requirements, even at a later time. Everything is perfectly matched, including the dosing station, the dissolver for solids and the buffer station.