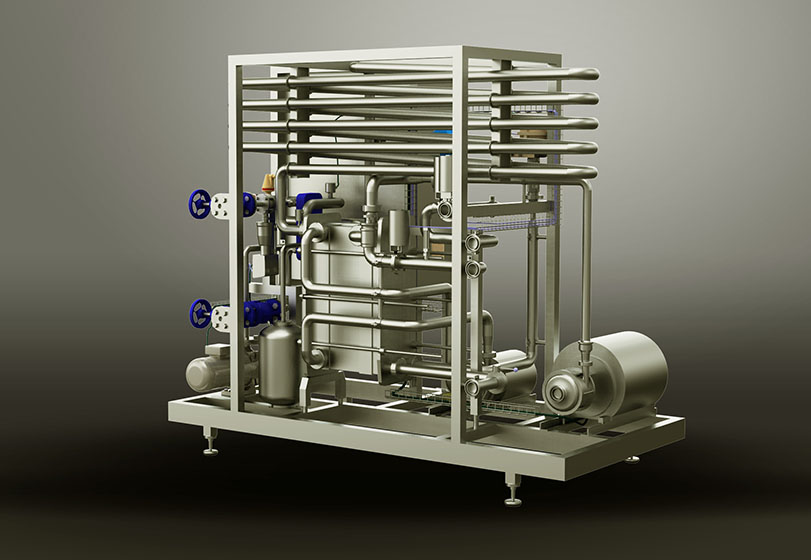

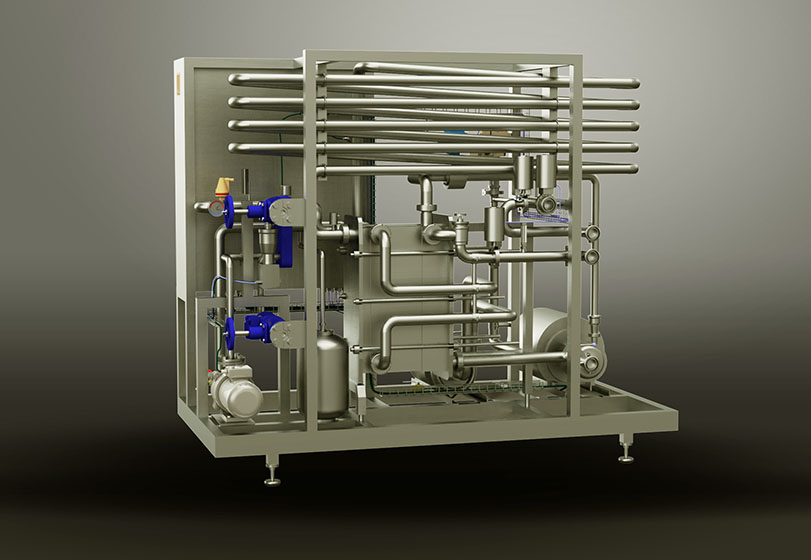

AMS FLASH

High-end pasteurisation plants for your products. Quality made in Germany, precise engineering and full automation at reasonable investments.

The two process parameters of pasteurization are temperature and holding time. The higher the temperature, the shorter the holding time and vice versa.

The general principle is to set the parameters in a way to meet shelf-life criteria while minimizing impact on taste quality.

Various established opinions are no longer state of the art. For example, a longer holding time has a more negative influence on the flavour than a slightly higher temperature. The demand for a higher heat recovery has a negative impact too, since it implicates a longer exchange zone. AMS FLASH principle is to achieve pasteurisation temperature as soon as possible, to shorten the holding time and to quickly cool down the product.

AMS FLASH is available

in 4 standard series for each capacity.

| AMS FLASH 32 | 5 m³/h | (60 hl/h) |

| AMS FLASH 50 | 11 m³/h | (120 hl/h) |

| AMS FLASH 65 | 20 m³/h | (230 hl/h) |

| AMS FLASH 80 | 35 m³/h | (350 hl/h) |

High-pressure systems for beer

and carbonated soft drinks

In the brewing industry, the process is straight-forward as beer is very durable by nature due to the pH value, alcohol, hop and CO2 contents. AMS FLASH securely destroys yeast cells and inactivates enzymes. The negative impact on taste is minimized due to low oxygen content of beer in combination with AMS FLASH treatment.

Low pressure systems

for fruit juice and milk

In the dairy industry, a distinction is made between pasteurisation and ultra-high temperature pasteurisation (UHT). Those terms relate to the different thermal treatments and thereby the attainable durability. Technically there are only minor differences. AMS FLASH can equally run as UHT systems, usually at heating temperatures between 120° and 150°C. The AMS FLASH incorporates detailed process engineering solutions superior to standard pasteurisation systems.

Shell and tube heat exchanger systems for viscous and fibrous products

Pasteurisation of viscous and chunky products or products with high fibre content requires use of double pipe heat exchangers. AMS FLASH is a complete module with pumps, valves and control systems. The double pipe heat exchangers are installed as a block next to the AMS FLASH. With these systems, the time for heating up and cooling down has to be taken into consideration when calculating the pasteurisation units.

A lot of value, and AMS FLASH reduces your investment and operating cost, while being reliable, durable, and easy to operate. German engineering for world-wide operations.

AMS FLASH is a compact design optionally equipped with plate, shell or tube heat exchanger. It is fully automated with Siemens PLC and coloured touch control panel. Remote maintenance, operation from a central control and integration into various process control systems is possible and all operating conditions are recorded. Specified pasteurisation units are automatically kept within a very narrow tolerance range. Throughput rate is adapted to buffer tank fill level, and if fill level increases, for example due to a fault in the bottling plant, the output is reduced automatically.