WATER DEGASSING AND JUICE DEGASSING

AMS water degassing and beverage degassing solutions focus on Gas Stripping with either hot or cold degassing solutions.

Attainable residual oxygen in the degassed water may be less than 0.02mg (ppm) O2/litre or less than 20µg (ppb) O2/litre.

The value for the residual oxygen is dependent on the oxygen content and the temperature of the raw water. The cooling of the water should therefore always take place after the water degassing. The column diameter and the column height are determined based on water temperature, oxygen content in the raw water, the desired throughput rate and the permitted residual oxygen.

Basis of every drink: Water

Oxygen can be removed from the water without too much difficulty and it represents the best value method for ensuring good product quality right from the start. The expression "degassed water" refers to the reduced oxygen content.

Oxygen in foodstuffs

During the production of beverages, it is essential that the oxygen content is kept as low as possible. The presence of oxygen encourages aerobic germs such as mould fungus. Oxygen also has an unfortunate effect on the colour and taste. This is particularly true if longer heat treatment is necessary. Oxygen reacts oxidatively with the amino acid methionine, ascorbic acid (vitamin C), flavonoids (secondary plant products) and unsaturated fats and lipids. Oxygen also encourages photosensitised oxidation (triggered by visible light) in beverages with transparent packaging. The shelf life of beverages is thus strongly dependent on the residual oxygen content.

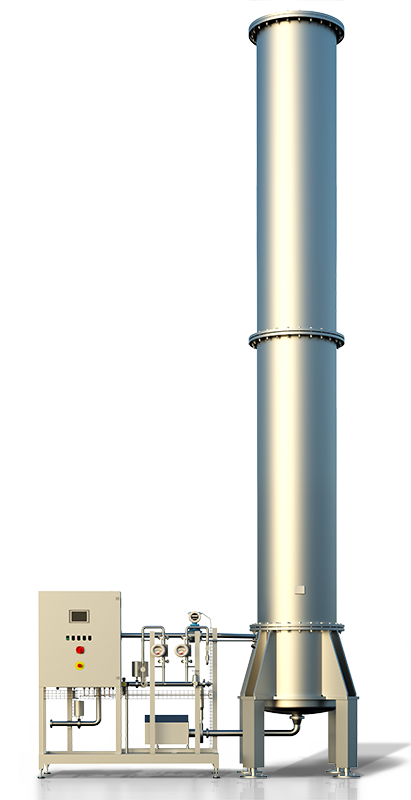

Gas Stripping (Desorption) Column - Water Degassing

In the stripping process a gas is guided over a thin film of the water to be degassed in a counter current configuration. The stripping gas removes the dissolved oxygen from the water (desorption) and guides it into the gaseous phase. The pressure inside the column corresponds to that in the surrounding atmosphere outside the column. The gas is dissipated into the atmosphere (via the roof). The great advantage of this process is its simplicity. The plants are incredibly quiet as no vacuum pump is required. N2 (nitrogen) is recommended to use as stripping gas for still beverages, whereas CO2 is recommended for carbonated beverages. The degassed water is buffered with CO2. The tendency to recontamination with oxygen is thereby reduced. The CO2 used is added to the product in large quantities. The effective additional consumption of CO2 is very low compared with a vacuum degassing plant.

AMS COLD DEGAS

The degassing process takes place completely at the temperature of the incoming water. This process always has the lowest energy consumption with the same output even though the column is the highest. The plant is extremely robust and there are hardly any wearing parts. The plant can be manufactured economically for many different sizes. Even for very small outputs.

Downstream UV sterilisation must be integrated if there are problems with the hygiene of the raw water. If severe problems with water hygiene are anticipated, then preference should be given to pasteurisation.

Gas requirement: approx. 0.22 kg/hl water, amount lost: approx. 5% (rest remains in the water)

| AMS COLD DEGAS 15 | max. 1,2 m³/h | (12 hl/h)) |

| AMS COLD DEGAS 25 | max. 3 m³/h | (30 hl/h) |

| AMS COLD DEGAS 32 | max. 6 m³/h | (60 hl/h) |

| AMS COLD DEGAS 50 | max. 12 m³/h | (120 hl/h) |

| AMS COLD DEGAS 65 | max. 23 m³/h | (230 hl/h) |

| AMS COLD DEGAS 80 | max. 35 m³/h | (350 hl/h) |

| AMS COLD DEGAS 100 | max. 55 m³/h | (550 hl/h) |

| AMS COLD DEGAS 125 | max. 86 m³/h | (860 hl/h) |

- Downstream carbonation

- Cooling

- UV sterilisation

AMS HOT DEGAS

Hot degassing offers the benefit of additional pasteurisation and is the ideal choice if problems with water hygiene are anticipated. Little energy is required for operating the plant due to the high level of heat recovery. The water enters the plant cold and leaves it cold as well. The increase in temperature due to pasteurisation is only approx. 8°C even if no cooling zone is provided in the heat exchanger (available as an option). In principle, no CIP cleaning or sterilisation is required due to the hot operation and the internal sterilisation steps during start-up. Acid cleaning should only be carried out occasionally depending on the hardness of the water.

Gas requirement: approx. 0.10 kg/hl water, approx. 5% of this is lost (via the roof, rest remains in the water)

AMS HOT DEGAS is available in 8 standard series for each capacity.

| Size | Throughput | Steam | |

| AMS DEGAS 32 | max. 6 m³/h | (60 hl/h)) | 76 kg/h |

| AMS DEGAS 50 | max. 12 m³/h | (151 hl/h) | 151 kg/h |

| AMS DEGAS 65 | max. 23 m³/h | (288 hl/h) | 288 kg/h |

| AMS DEGAS 80 | max. 35 m³/h | (439 hl/h) | 689 kg/h |

| AMS DEGAS 100 | max. 55 m³/h | (550 hl/h) | |

| AMS DEGAS 125 | max. 86 m³/h | (860 hl/h) | 1078 kg/h |

AMS JUICE DEGAS

The AMS JUICE DEGAS is a high-end module for degassing of any fruit juice.

The degassing takes place on a rotating plate within an evacuated tank, the rotation of the plate allows the product to be flung evenly against the tank wall forming a thin film. The vacuum separates the gases from the product film which are sucked out. A specific quantity of steam is removed depending on the set temperature. This steam and the contained flavours are condensed in a heat exchanger and then directly fed back into the product. The components which cannot be condensed are removed from the system with a vacuum pump.