SYRUP KITCHEN - perfect soft drink factory

The Syrup Kitchen is your hub for creating innovative drinks. Highest syrup quality, flexibility in recipe design and preparation of syrup variants. That’s the AMS guarantee. Tasty soft drinks, juice spritzers, juice beverages, alcohol-based cocktails or energy drinks. The choice is yours.

For the production of mixed beverages a syrup can be prepared as a primary product. Syrup is made essentially of liquid sugar and flavour. A high quality syrup production should also ensure that the oxygen content of the liquid sugar is reduced. A carbonation of the syrup provides finer resolution of the CO2 in the finished beverage.

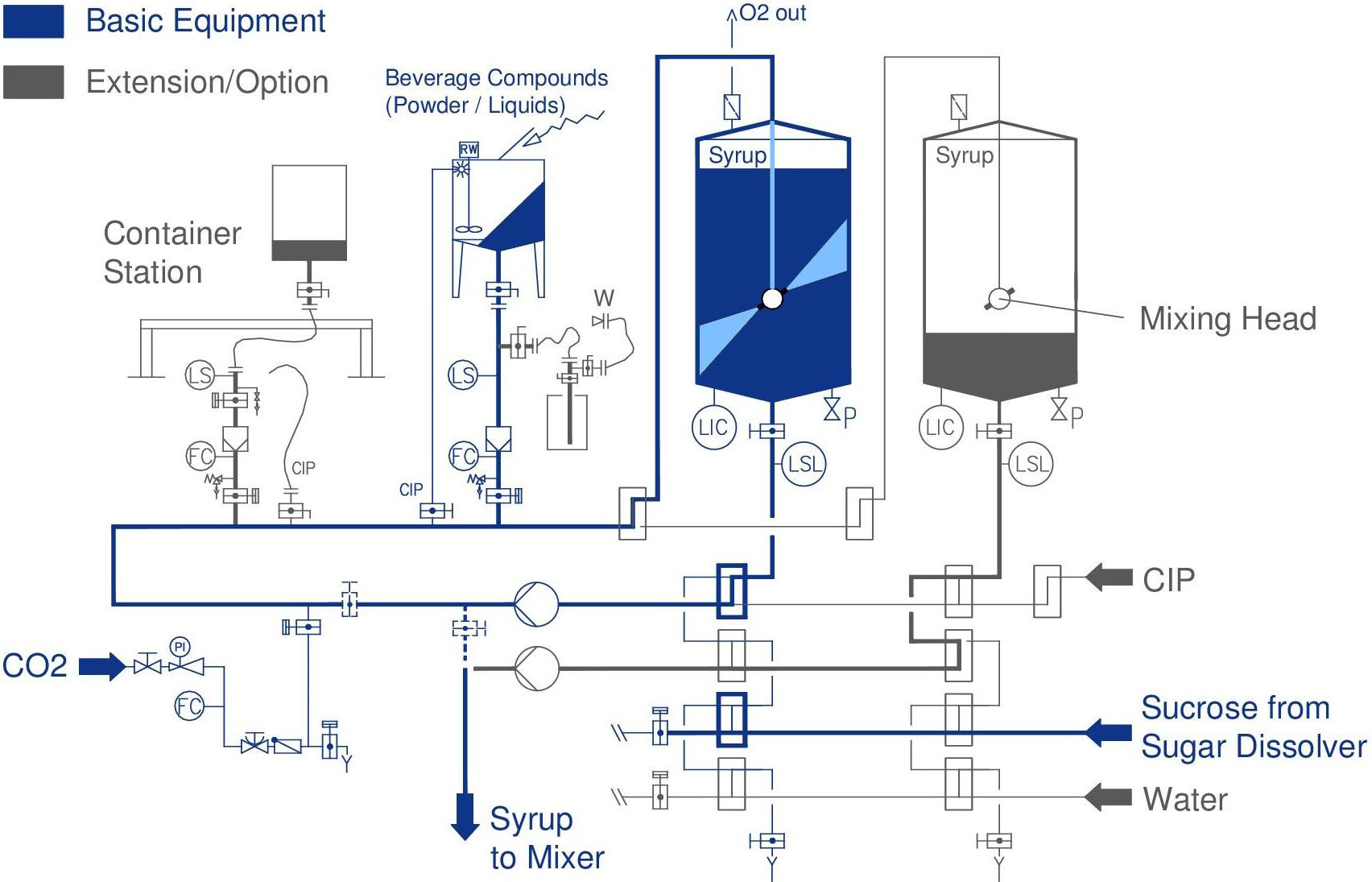

Our syrup rooms consist of the following components:

- Mixing tanks

- Syrup routing module

- Container station

- Dissolver for solids / addition of micro ingredients

- Suction lance

The syrup production is carried out in a batch mode. If two syrup tanks are used, the syrup can be prepared continuously. The special feature of our syrup room is the unsurpassed perfectly mixed syrup, a lower oxygen content and the pre-carbonation of the syrup. Liquid sugar usually contains a lot of oxygen, depending on the dissolution process.

By the addition of CO2 into the circulation line, the oxygen is expelled from the syrup. What remains is a desired pre-carbonation of the syrup. If non-carbonated drinks are produced, then instead of oxygen, nitrogen may be used or there may be no addition of gas.

#1. Mixing tanks

The mixing tanks are equipped with rotary mixers. With the mixers a perfectly homogeneous mixing result is ensured in a very short time. The addition of gas is also made via the rotary mixers. In the CIP cleaning the rotary mixers act as cleaning heads and provide a perfect cleaning of even the bottom of the upper tank.

#2. Routing module

The routing module is the function module to which all modules of the syrup room are connected. The control panel is also placed on the routing module. The syrup room is controlled from here.

#3. Container station

If the beverage ingredients are delivered in IBC containers or 500/1000 litre stainless steel containers, our container station simplifies the handling considerably. The operation takes place at normal working height. The container changing can be done simply without oxygen intake into the syrup. The pump, the measurement devices (mass flow), low level probe and the valves are housed in the container station. All pipes and hoses are completely integrated into the automatic CIP cleaning. The container station can be upgraded with additional spaces.

#4. Dissolver

For solids / addition of micro ingredients

If ingredients are solid, then our dissolver is the optimal choice. Our dissolver is also suitable for adding small amounts of liquid components. The dissolver unit takes care of a homogeneous mixture prior toin front of dosing into the syrup tank.

#5. Suction lance

If raw materials are supplied in barrels, the barrel content must be removed from the top of the tank. The lance has an integrated water channel. With this the tube content can be applied to the product. The suction pipe is connected to the container station or to the solid solvent.