HIGH GRAVITY BREWING - HGB

High Gravity Brewing enables a brewery to exploit its resources to the maximum. Additionally, a precise adjustment of the naturally fluctuating wort can be achieved.

Beer treatment occurs extremely gently with our modules. There are neither sintered candles nor dead areas hard to clean, nor are beverages exposed to shear forces. Our systems are robustly designed including the measurement devices, which is especially in faraway regions a benefit. The High Gravity Brewing modules are based on a CIP cleaning concept guaranteeing a high degree of safety regarding mixing, even the CO2 pipe can be CO2 cleaned.

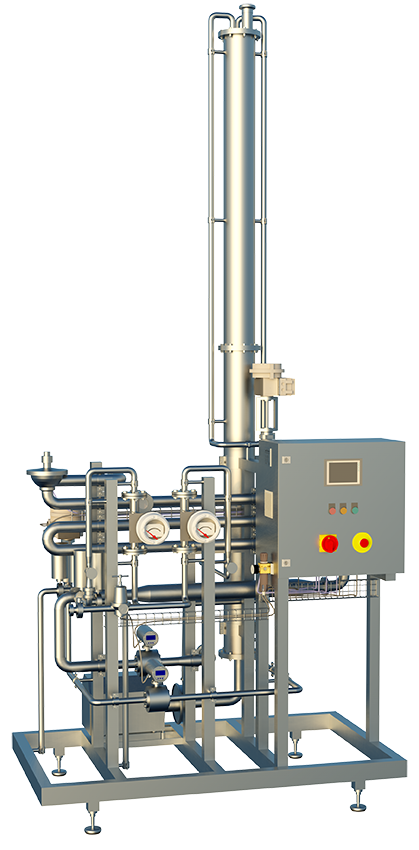

AMS SMART HGB - High Gravity Brewing

Semi-automatic High Gravity Brewing module with reliable and consisten outputh

AMS SMART HGB is an extremely robust and easy to operate system at restricted budget. Rough ambient conditions such as water hammers in the pipework or power failures will hardly cause any damage. The system is precise to eliminate variations of product batches, even the technology is kept simple. The system is implemented according to the expansion stages required. The degassed water could be produced within AMS SMART HGB by adding a small degassing column to the system

AMS SMART HGB is available in 2 standard series for each capacity.

| AMS SMART HGB 32 | max. 5 m³/h | (50 hl/h) |

| AMS SMART HGB 50 | max. 10 m³/h | (100 hl/h) |

AMS AUTO HGB - High Gravity Brewing

Fully automatic High Gravity Brewing module with low operating cost

The system regulates the predefined values for the CO2 content, the original wort and the beer colour automatically. The unique design of the dosing technology is the system's unique feature. The components to be dosed are added precisely at the same dosing point for both homeopathic or high dosing rates. There is in principle no competing system which can achieve a higher level of accuracy while being kept clean so easily with CIP cleaning.

AMS AUTO HGB is available in 6 standard series for each capacity.

| AMS AUTO HGB 32 | max. 6 m³/h | (60 hl/h) |

| AMS AUTO HGB 50 | max. 12 m³/h | (120 hl/h) |

| AMS AUTO HGB 65 | max. 23 m³/h | (230 hl/h) |

| AMS AUTO HGB 80 | max. 35 m³/h | (350 hl/h) |

| AMS AUTO HGB 100 | max. 55 m³/h | (550 hl/h) |

| AMS AUTO HGB 125 | max. 86 m³/h | (860 hl/h) |

Precision attainable:

CO2 dosing: +/- 0.05 g/litre deviation from target value CO2 content finished product

water dosing: +/- 0.1° Plato

colouring beer dosing: +/- 0.1% deviation from target value colouring beer dosing volume