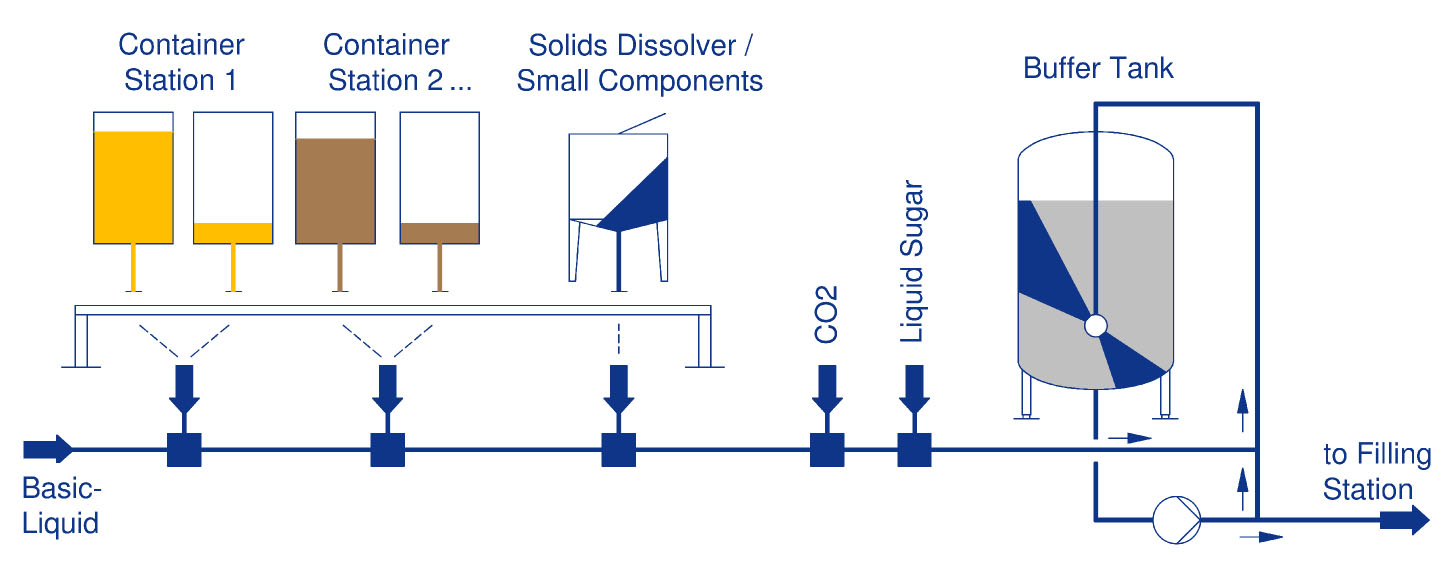

SUGAR DISSOLVING - for perfect soft drink production

AMS BRIX sugar dissolving solutions are setting the next technology standard for soft drink production. AMS BRIX solutions are process optimized to prevent product spoilage germs and oxygen contained in sugar to effect dissolved sugar and hence soft drinks.

Addition of granulated sugar

from bags (25/50kg)

& from big-bags

recommended for capacities

less than 2000 liters/h

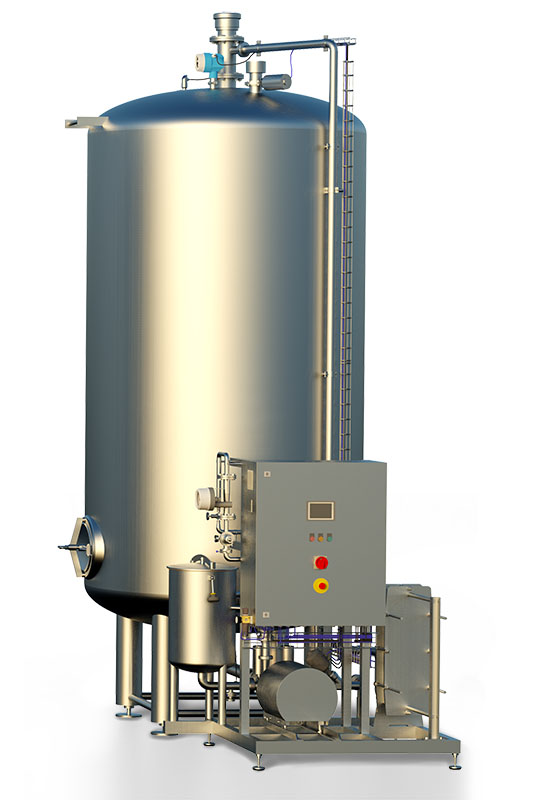

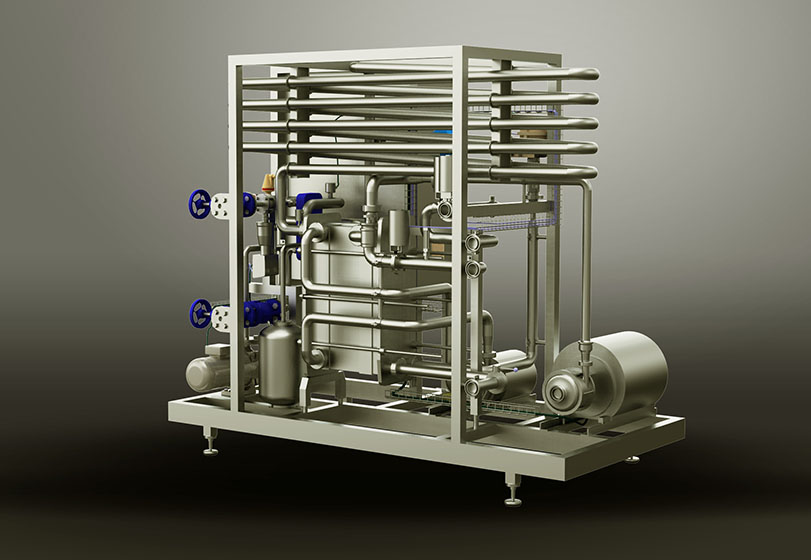

AMS CONTI-BRIX

Unmatched low heat requirement

and no recrystallisation!

This sugar dissolving system is characterised by its unbeatably low heat demand. This is not the only reason why AMS CONTI-BRIX is the best sugar dissolver on the market. The only precondition is a constant sugar demand and that concentration of sugar syrup must not exceed 70 Brix. Cold crystal sugar is mixed with cold water, in that way no vapours are generated blocking the dosing equipment for granulated sugar. Hot sugar dissolving takes place within the system. Finally, the hot sugar syrup is cooled to the desired syrup temperature by the water-sugar suspension in the countercurrent heat exchanger.

Sugar dissolved with AMS CONTI-BRIX remains free from any recrystallization for a very long time, due to hot dissolving in continuous flow mode. No recrystallization germs (e.g. undissolved sugar from tank walls, etc.) can pass through the system and hence not in the final soft drinks.

Max: 70 Brix

Capacities from 2,000 kg/h up to 20,000 kg/h

Addition of granulated sugar

from a silo

and from big-bags

recommended for capacities

over 2000 liters/h

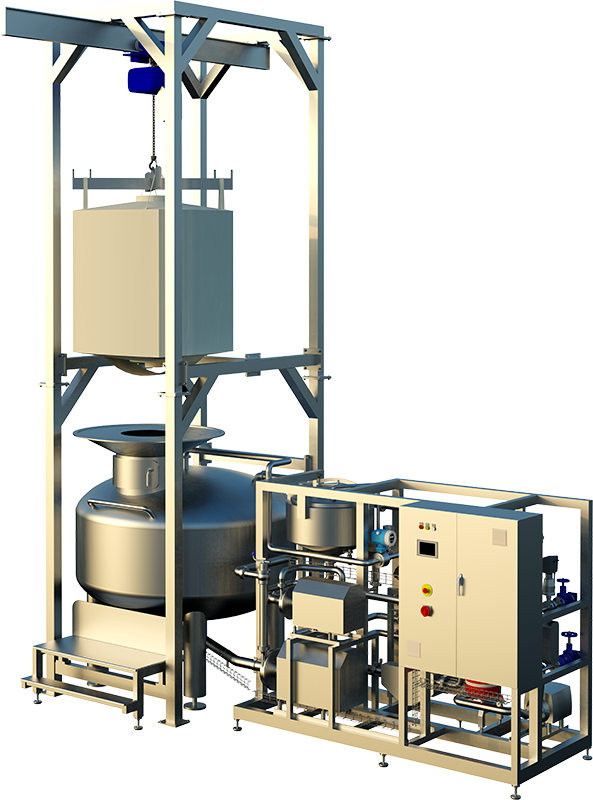

AMS BATCH-BRIX

A batch sugar dissolving system is used if the granulated sugar is received from bags/big bags instead of sugar silos, or in case the demand for liquid sugar is not continuous. The AMS BATCH-BRIX is available for various batch sizes.

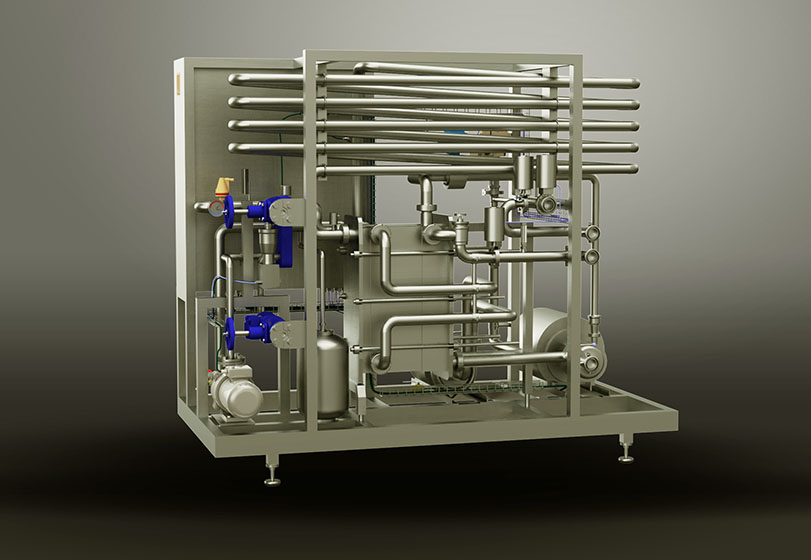

AMS BATCH-BRIX-MAX

Cleanliness and high performance sugar dissolving

This concept is designed for high or even continuous production rates. The feed hopper for granulated sugar is positioned away from the other devices. This allows a barrier-free feeding of granulated sugar. The picture shows all three components of the system: two sugar dissolving tanks, sugar feeding station and distribution module. A continuous sugar deployment is possible if two liquid sugar tanks are provided. The distribution module provides sugar filtration, tank changing, dosage of the liquid sugar to the consumers, circulation and temperature control as well as cleaning management.

AMS BATCH-BRIX-COMPACT

The sugar dissolving system for medium-sized companies

The sugar dissolving system is based on a common stainless steel frame, only the dissolving vessel is placed separately. The sugar dissolving vessel and the sugar dissolving plant are connected to the customer's facility by a swivel bend panel. The system can be equipped with a heater as shown. AMS BATCH-BRIX-COMPACT may be ideal if installation space is limited.

AMS BATCH BRIX FLEX

Affordable and flexible sugar dissolving

If the quantity of sugar dissolving is manageable and other substances may be added, then AMS BATCH BRIX FLEX is the right solution. The dissolving tank is located on the common base frame. The granulated sugar is dissolved straight into the tank by the operator. AMS BATCH BRIX FLEX allows production of liquid sugar with very high Brix values.

SIX ACCESSORIES

for sugar dissolving systems

#1 - Additional module heat and water recovery for sugar dissolving systems

Certain applications require the provision of cold sugar syrup. The heat from the hot solution must be fully removed in this case. Our module for heat recovery allows this recovered energy to be used in the hot solution of the sugar. In contrast to conventional recovery systems, no excessive hot water quantities are generated, which cannot be used otherwise.

#2 - Brix-Control module

If there is a high demands of exact sugar syrup concentration, then the Brix-Control module is recommended. The sugar is dissolved with a slightly higher concentration and then diluted by water to the target value. The fully automated system includes Brix measurement to achieve accuracies of up to +/- 1° Brix.

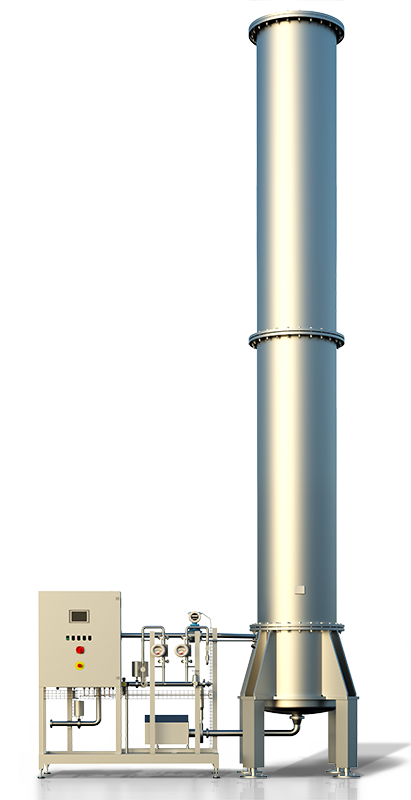

#3 - Syrup filtration and syrup decolouration (activated carbon filter)

With granulated sugar foreign particles will always enter the sugar syrup. These particles can easily be filtered out of the liquefied sugar (syrup). We offer filter systems with different filtration grades for this purpose. If clear beverages are being produced, we recommend our activated carbon filter. As a result, discolorations in the granulated sugar will not appear in the dissolved sugar syrup.

#4 - Sugar storage tanks and ring circuit

The sugar syrup is provided in insulated and heated storage tanks. A circulation line is used to guide the sugar to the points of use and back to the respective storage tank.

The advantages of this system are considerable:

- sedimentation in the storage tanks or in the pumps is prevented

- the ring circuit is always free from air

- the ring circuit can be rinsed easily with hot water

- no sugar losses while feeding the sugar to the dosing point

- no sugar spreading, no damage to the floor coating

#5 - Syrup dosing system

Our dosing system guarantees an unsurpassed precision in the dosing of the sugar syrup into your product. The homogeneous blending of the syrup is always ensured, even with cold products. Dosing is pulsation-free. Even the very smallest dosing rates are dosed accurately.

#6 - Crystal sugar handling

In continuous systems the granulated sugar is provided from a sugar silo. Then the dosing into the dissolving system is carried out via a rotary feeder or a dosing screw. With batch dissolving systems, the granulated sugar is provided via a screw conveyor or via our "PowderFeeder".